INFRASTRUCTURE

KNITTING

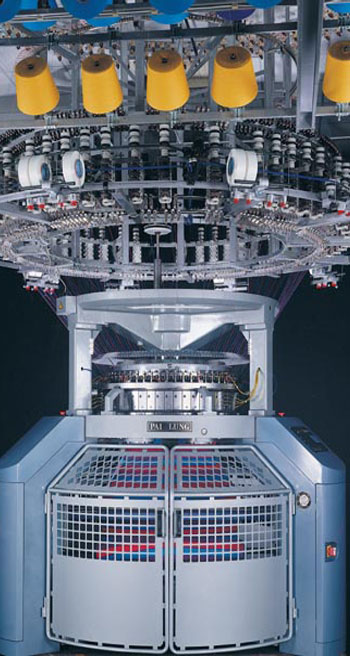

The process of knitting is carried out with utmost care and sophistication with 20 imported machines form ORIZIO, ITALY. The knitting factory got a production capacity of 8-10 tonnes of fabric per day. All the 20 machines are equipped with elasthan attaching devices and can able to produce Single Jersey, Loop Knit, Honey Combed, Rib, Inetrlock pique, Hat back Rib, Air Tex and Terry Knitting.

The process of knitting is carried out with utmost care and sophistication with 20 imported machines form ORIZIO, ITALY. The knitting factory got a production capacity of 8-10 tonnes of fabric per day. All the 20 machines are equipped with elasthan attaching devices and can able to produce Single Jersey, Loop Knit, Honey Combed, Rib, Inetrlock pique, Hat back Rib, Air Tex and Terry Knitting.

DYEING

Pratik Hosiery private Limited has its own dye-house at Erode, a neighbouring Textile town. This unit is a OEKO-TEX Standard 100 Certified. It is fully equipped with latest technology machines - KROMSAN - TURKEY - HTHP dyeing machines, BIANCO - ITALY Baloon padding, FONGS - HONGKONG Relax dryer machines. It ensures the most accurate and uniform dyeing with a gentle treatment for better stability of the fabrics as well as softness strength of the output. The dye-house has the capacity of handling 10- 12 tons fabrics per day. It is supported by a latest technology effuluent treatment plant to ensures a cleaner environment. These machines can process all types of fabrics like 100% cotton Knitted Fabric, Polyester, Poly cotton, Modal, 100 % Viscose & Viscose Lycra.

Pratik Hosiery private Limited has its own dye-house at Erode, a neighbouring Textile town. This unit is a OEKO-TEX Standard 100 Certified. It is fully equipped with latest technology machines - KROMSAN - TURKEY - HTHP dyeing machines, BIANCO - ITALY Baloon padding, FONGS - HONGKONG Relax dryer machines. It ensures the most accurate and uniform dyeing with a gentle treatment for better stability of the fabrics as well as softness strength of the output. The dye-house has the capacity of handling 10- 12 tons fabrics per day. It is supported by a latest technology effuluent treatment plant to ensures a cleaner environment. These machines can process all types of fabrics like 100% cotton Knitted Fabric, Polyester, Poly cotton, Modal, 100 % Viscose & Viscose Lycra.

COMPACTING

Consists of Tube-tex, USA Tubular and Open Width Compacting Machines -1 Nos. Also Tong Geng Chamber Heat Setting Machines for Lycra and Polyester Fabrics which can handle fabrics up to a width of 48 Inches. The capacity of the Compacting Department is 4 Tons of fabric per day.

Consists of Tube-tex, USA Tubular and Open Width Compacting Machines -1 Nos. Also Tong Geng Chamber Heat Setting Machines for Lycra and Polyester Fabrics which can handle fabrics up to a width of 48 Inches. The capacity of the Compacting Department is 4 Tons of fabric per day.

PRINTING

The prnting factory is capable of handling Exclusive and innovative designs with multi colour placement print machines. It has the table printing facility also. The total capacity is around 14000 prints per day.

The prnting factory is capable of handling Exclusive and innovative designs with multi colour placement print machines. It has the table printing facility also. The total capacity is around 14000 prints per day.

EMBROIDERY

Special type embroidery works are being carried out by using 12*20 head BARUDAN - JAPAN Embroidery machines with capacity of 6000 pcs per day.

Special type embroidery works are being carried out by using 12*20 head BARUDAN - JAPAN Embroidery machines with capacity of 6000 pcs per day.

IN-HOUSE FACILITIES

Our factory located at heart of Tirupur is built in 10,000 Sq. ft. area. We possess state of art manufacturing facilities. It includes complete in house stitching/finishing using best of machines & most important using latest technology & specialized Machine. Different type of folders guides & attachments are used to enhance the productivity.

Our factory located at heart of Tirupur is built in 10,000 Sq. ft. area. We possess state of art manufacturing facilities. It includes complete in house stitching/finishing using best of machines & most important using latest technology & specialized Machine. Different type of folders guides & attachments are used to enhance the productivity.

DESIGN & DEVELOPMENT TEAM

Our expertise in the manufacturing of fashion apparels as per the customized styles, designs and other specifications provided by our customers. The extensive process experience of our designers and associated workforce enables us to clearly understand and meet the specified order demands.

Our expertise in the manufacturing of fashion apparels as per the customized styles, designs and other specifications provided by our customers. The extensive process experience of our designers and associated workforce enables us to clearly understand and meet the specified order demands.

CUTTING

Fabric cutting that ensures the desired styles has been perfected with the use of computerized Lectra CAD markers. Our sewing facility sprawls over 4 different units, strategically located in the same vicinity with the combined capacity of 15,000 units/day in fashion styles.

Fabric cutting that ensures the desired styles has been perfected with the use of computerized Lectra CAD markers. Our sewing facility sprawls over 4 different units, strategically located in the same vicinity with the combined capacity of 15,000 units/day in fashion styles.

Lay cutting machines with automatic spreader that are highly advanced are been installed in our product unit. A separate squad is been appointed to make quality check fabric cut and stitching! To avoid angle variations in shape, we use effective band knife cutting machines.

GARMENTING

Modernized sewing machines with the latest features have been imported and being used for our production process. There are 300 sewing machines now in use.

Modernized sewing machines with the latest features have been imported and being used for our production process. There are 300 sewing machines now in use.

CHECKING

Inspection/Finishing Unit independent of production to ensure the Quality and Specifications of Buyers are met.

Inspection/Finishing Unit independent of production to ensure the Quality and Specifications of Buyers are met.

IRONING

Stream Ironing the Finished products to packing quickly. Garments are steam processed.

Stream Ironing the Finished products to packing quickly. Garments are steam processed.

PACKING

Garments are packed neatly in the designated packs and placed inside the carton or hanger racks for dispatch.

Garments are packed neatly in the designated packs and placed inside the carton or hanger racks for dispatch.